Facilities

Our facilities feature an innovative MSW Characterization system that uses advanced technologies to procure, concentrate, characterize, and separate waste materials and convert them into valuable resources. We are committed to Sustainable Waste Management (SWM) and continuously explore new technologies and solutions to reduce waste and protect the environment.

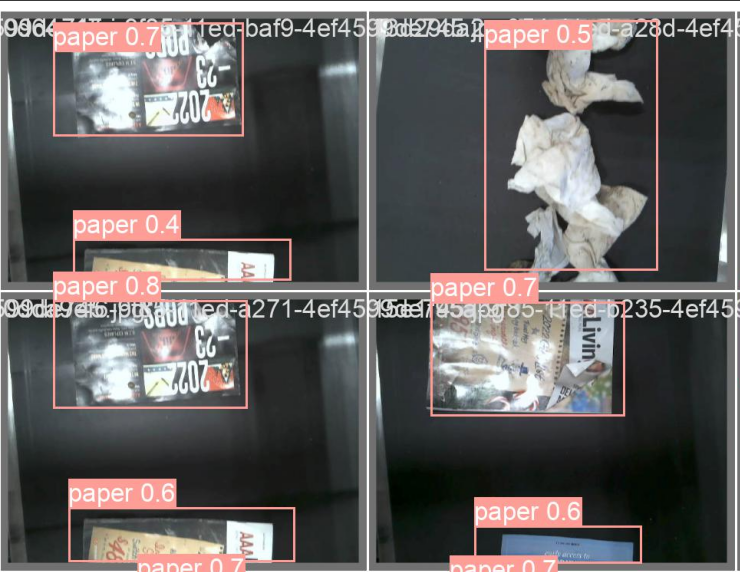

Real-Time MSW Characterization System

Our waste management system will boast advanced capabilities. By incorporating state-of-the-art hyperspectral imaging, computer vision, and machine learning algorithms, we can quickly and precisely identify and classify different waste materials in real-time.

Hyperspectral cameras

Hyperspectral cameras play a critical role in our waste management project as they provide high-resolution imaging capabilities that enable us to capture detailed information about waste materials.

By using hyperspectral cameras, we can identify and analyze the unique spectral signatures of various waste materials, which allows us to rapidly and accurately classify and sort them.

Cameras & Sensors

Visual cameras are a critical component of our waste management system, allowing for the creation of a comprehensive repository of waste images that can be used to train our machine learning algorithms.

In addition to visual cameras, our system also utilizes a variety of sensors to monitor and control the waste management process.

Conveyor belts

We employ conveyor belts to transport waste materials through the sorting process.

These conveyor belts are designed to handle a variety of waste types and sizes, providing a smooth and efficient means of transportation.

IoT devices

Computer vision systems

Machine learning algorithms

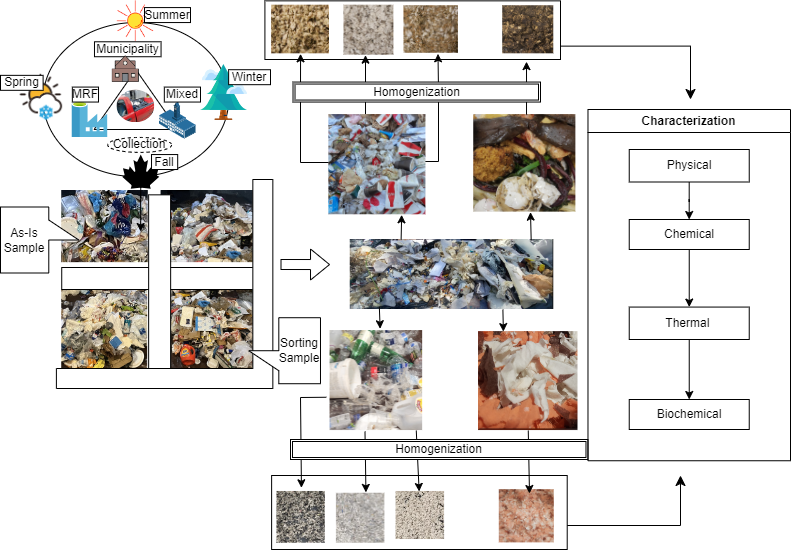

Municipal Solid Waste Characterization

By employing comprehensive characterization techniques and utilizing our well-equipped facilities, we strive to extract maximum value from municipal solid waste. Through careful analysis and understanding of waste composition, we can identify viable pathways for its valorization, contributing to a more sustainable and circular economy.

Physical

Chemical

Biological

Chemical Analysis:

Our state-of-the-art facilities allow us to perform extensive chemical characterizations of sorted and homogenized MSW samples. Through proximate analysis, we gain insights into the moisture content, volatile matter, fixed carbon, and ash content. This data is invaluable for informed decision-making and process optimization.

Ultimate Analysis:

By conducting elemental analysis, we determine the carbon, hydrogen, nitrogen, oxygen, and sulfur content of the MSW samples. This information enables us to calculate the high heating value, providing crucial insights into the energy potential of the waste material.

Composition Analysis:

Understanding the composition of the waste biomass is essential for valorization efforts. Our chemical analysis techniques, coupled with NREL standards, enable us to identify and quantify cellulose, hemicellulose, lignin, glucose, and other sugars. This comprehensive analysis guides us in identifying the optimal valorization pathways for different waste samples.

Fourier Transform Infrared (FTIR):

Our advanced FTIR testing allows us to identify the functional groups present in the waste samples. This analysis is particularly useful for confirming any changes resulting from pretreatment or other processes, empowering us to fine-tune our sorting and valorization strategies.

X-RAY Fluorescence (XRF):

To accurately quantify the presence of metallic elements in MSW samples, we employ X-ray fluorescence. This information is vital for assessing contamination levels and developing effective waste management plans.

Scanning Electron Microscopy (SEM):

We use this advanced surface analysis tool for studying surface morphology, particle size and elemental composition of different MSW fractions. SEM produce high resolution pictures of solid and therefore identifies back scattered electrons indicating the content of MSW samples.

Thermogravimetric Analysis (TGA):

Our advanced TGA facility enables us to get valuable insights into the thermal behavior, quantification of moisture content, detection of hazardous content and composition of MSW fractions such as plastic, paper, food and textile. It also helps in estimating the organic content of MSW by observing the weight loss associated with the degradation of organic materials.

X-ray diffraction analysis (XRD):

It gives us information about the crystalline phase, phase composition and helps us understand the thermal transformation in waste materials when exposed to high temperatures.

Calorific Value:

Using a bomb calorimeter, we determine the calorific value of the waste samples. This analysis provides crucial insights into the energy emission and heat rate of the waste material, supporting informed decision-making for its efficient utilization.

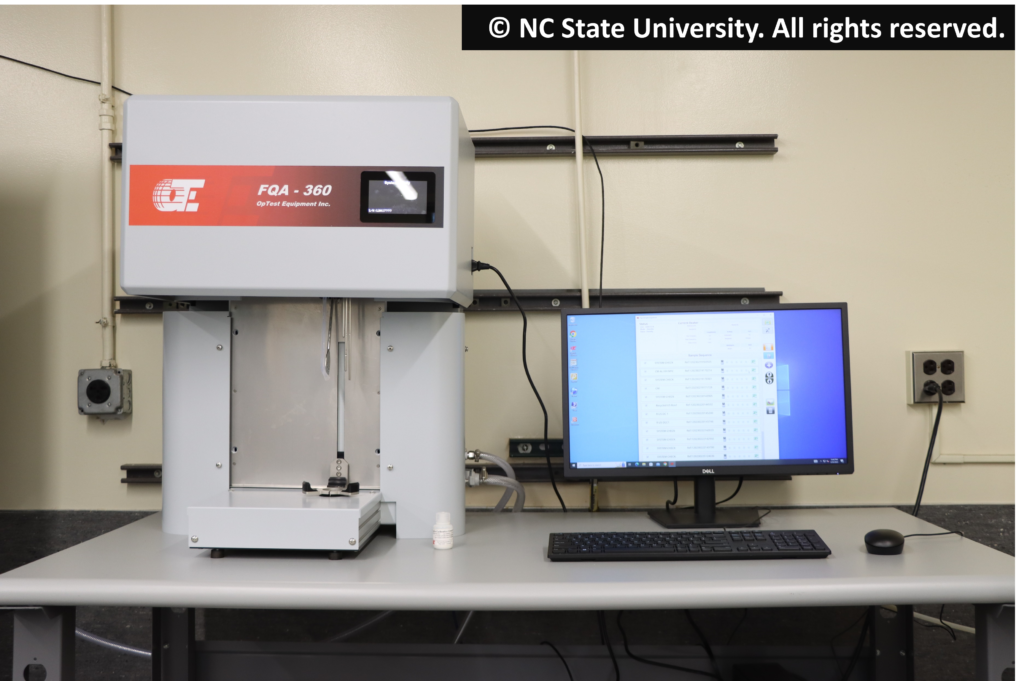

Fiber Quality Analysis (FQA):

For both recycling and enzymatic hydrolysis purposes, understanding the fiber quality of waste materials is paramount. Our FQA examines parameters, such as fiber length, fine contents, and kinks, allowing us to evaluate the compatibility of the waste for further valorization efforts.

Differential Scanning Calorimetry (DSC):

By understanding the thermal behavior of waste materials during incineration or pyrolysis processes, we are able to predict the formation of pollutants or harmful emissions and devise methods to mitigate them. This information can aid in waste separation, recycling, and disposal strategies.

Gas Chromatography-Mass Spectrometry (GC-MS):

GC-MS’s ability to separate and identify complex mixtures makes it an indispensable tool in the quest for valuable compounds within MSW. From bioactive substances to recyclable polymers, GC-MS enables us to pinpoint and quantify these hidden treasures, reshaping waste streams into resource streams.

MSW Valorization Pathways

We are dedicated to revolutionizing waste management through innovative solutions. Our focus lies in the cutting-edge process of valorizing municipal solid waste into biofuels and different range of high value products.

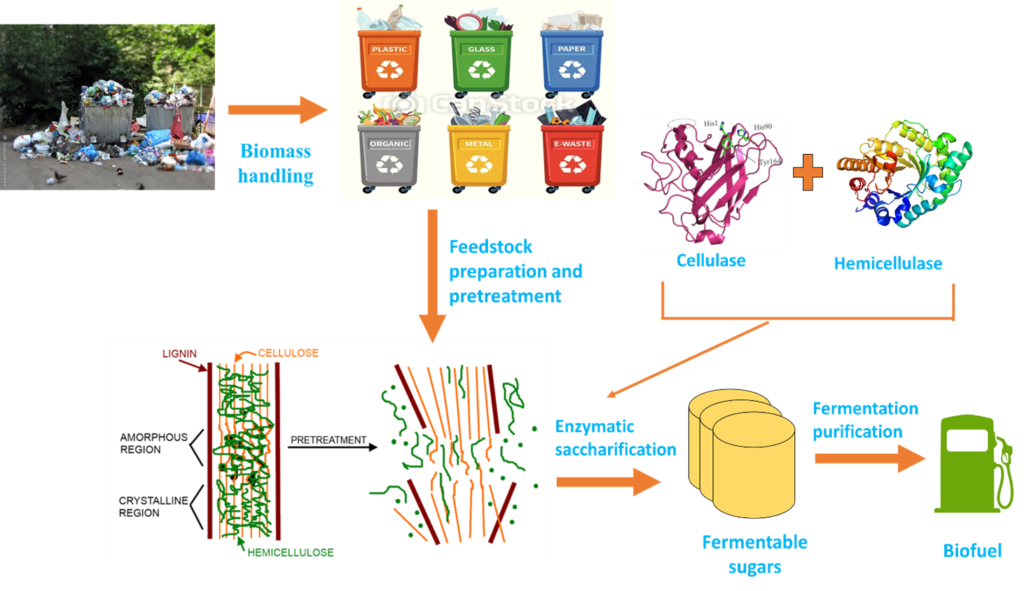

Transforming MSW into biofuel and value-added products

Our state-of-the-art valorization process involves a series of sophisticated steps that transform waste materials into clean and renewable biofuels that can power our world.

Optimizing waste valorization: The importance of pretreatment steps

One of the important features of our approach lies in the strategic application of different physical, chemical, and biological pretreatment methods in preparing MSW for conversion into valuable resources. We do mechanical extrusion, milling, grinding, and chipping to break down the substrate particles to homogenize and control physical, chemical and composition.

Chemical pretreatment: Unleashing the potential

This process is a key pillar in our approach, where we use mild acidic, alkali solutions, organosolv pretreatment, and steam explosion to remove lignin and break down the cellulose and hemicellulose into simple sugars. This results in increased porosity and enhances the accessibility of enzymes during enzymatic hydrolysis and enabling more efficient sugar release.

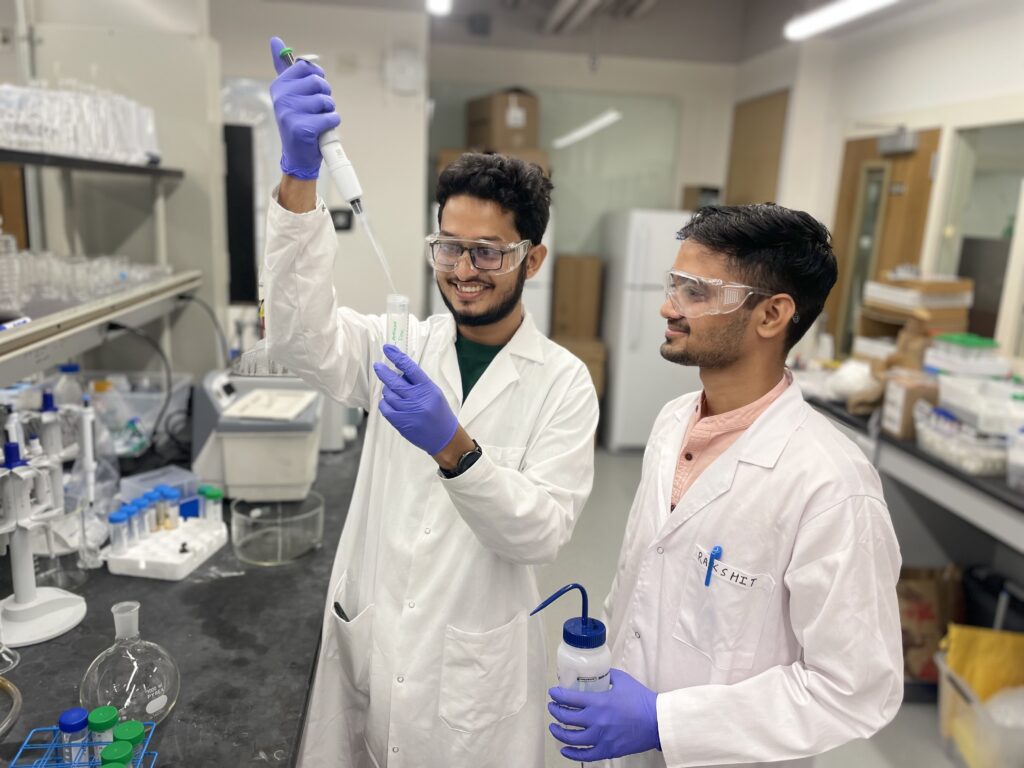

Breaking down barriers: Enzymatic hydrolysis of pretreated biomass

At the heart of our approach lies the enzymatic hydrolysis process, a sophisticated biochemical process that converts complex sugars in pretreated biomass into simple sugars suitable for fermentation. We employ specialized enzymes, cocktails of cellulases and hemicellulases that target cellulose and hemicellulose present in the pretreated biomass. In addition, depending upon the complexity of biomass, we use other enzymes, such as lignin modifying enzymes, to help break down the lignin.

Achieving optimal enzymatic hydrolysis requires careful consideration of enzyme type, concentration, and operating conditions. Our expertise ensures that each parameter is finely tuned for maximum efficiency.

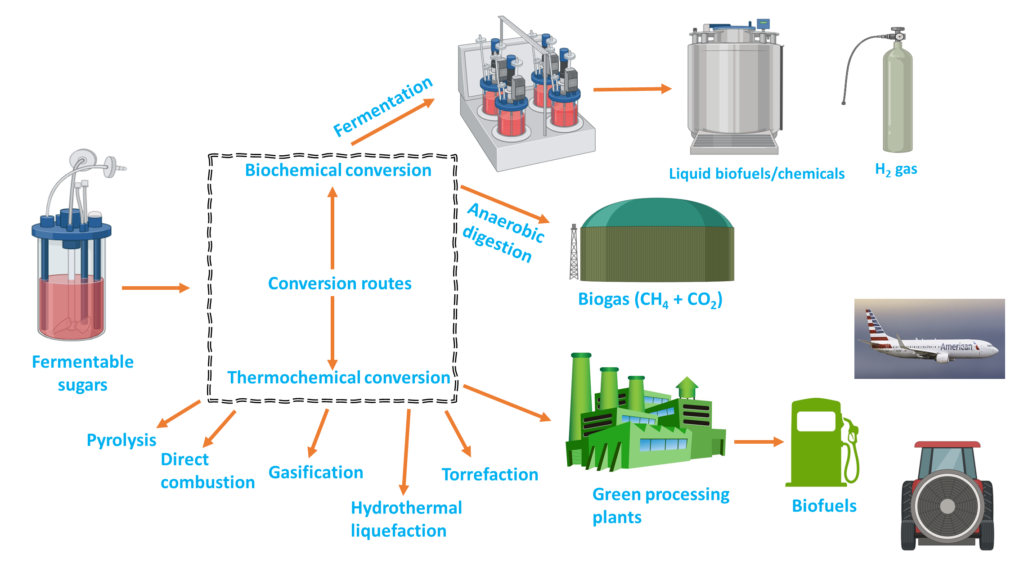

Fueling a greener future: Fermentation of biomass for sustainable energy

Our commitment to transforming organic biomass into biofuel through biochemical and thermochemical pathways is at the core of our mission. We are pioneers in sustainable fuel production through fermentation. We convert enzyme-treated biomass rich in glucose into different streams of biofuels such as ethanol, biodiesel, biogas, biohydrogen and biohythane, which is a mixture of H2, CH4, and CO2. Ethanol can be blended with gasoline or used as sustainable fuel in vehicles.

Hydrocarbon synthesis

We have the capabilities to convert enzyme-treated biomass into long-chain hydrocarbon, such as sustainable aviation fuel (SAF) by using advanced thermocatalytic technologies such as hydrothermal liquefaction or Fischer-Tropsch synthesis. These hydrocarbons can replace gasoline, diesel, and jet fuel.

Converting MSW to high value Biochar: A Sustainable Solution

Converting MSW into biochar is an innovative approach that addresses waste management, soil health, and climate change simultaneously. By transforming waste into a resource, we take steps toward a sustainable future. This process contributes to waste reduction, carbon sequestration, and improved agricultural practices.

Process Simulation and Modeling

Economic Analysis

Life cycle assessment (LCA)

Future Developments

As technology continues to advance, we are constantly looking for ways to improve our waste management system. In future developments, we aim:

- Automated sorting using robotics

- Expand the use of IoT devices and sensors to gather more spatial, temporal and spectral data

- Continually refine machine learning algorithms to improve the accuracy of waste classification

- Deployment of open-source AI-enabled cost-effective modular system for rapid/ real-time characterization of heterogeneous domestic MSW.

- Enable live prediction about MSW with a deployed AI model for citizen education, outreach, and DEI efforts.